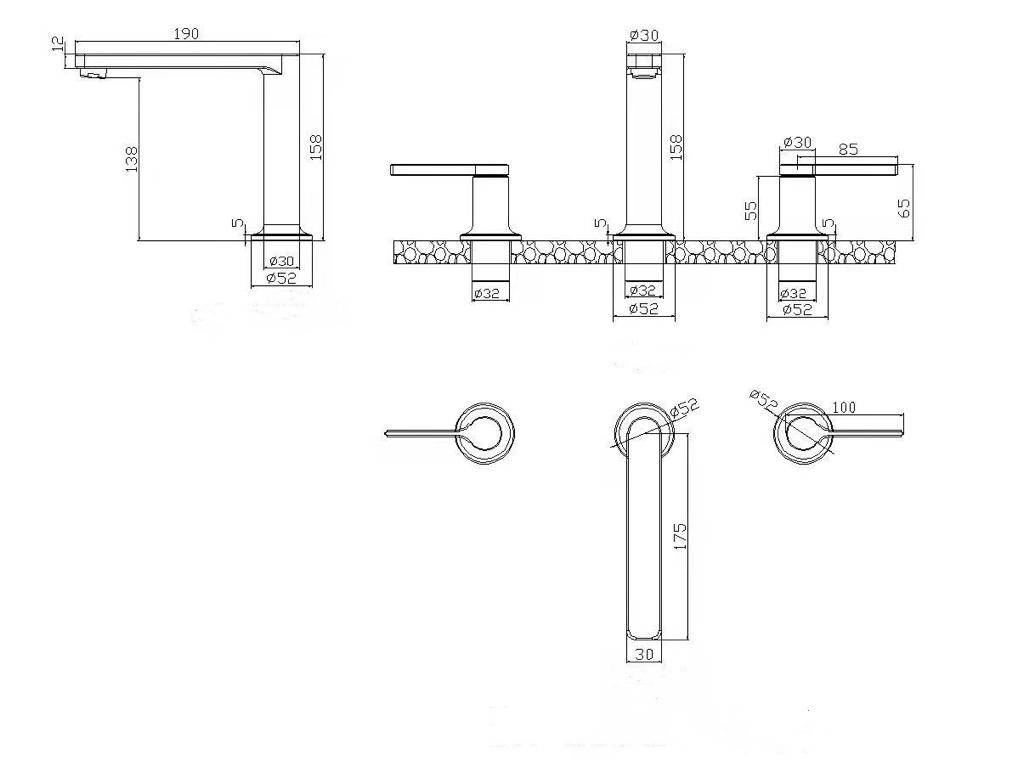

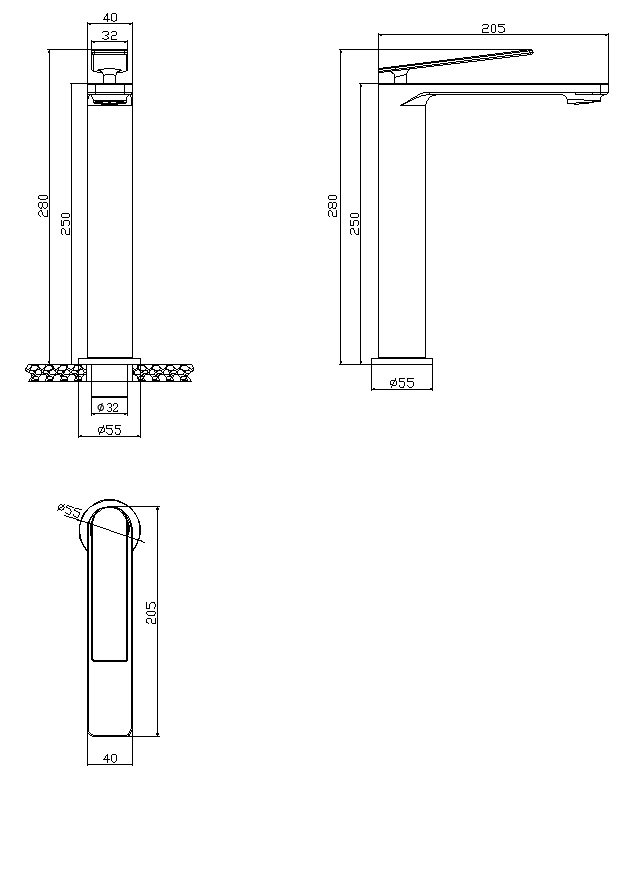

Axor Series Basin Mixer

3 hole basin mixer taps feature two separate controls and a central mixer spout, creating a sculptural look whilst being easy to use. This, therefore, means you are going to achieve a more precise water temperature. At SIGNATURE we provide a comprehensive range of both modern and traditional 3 hole basin taps featuring an array of many different beautiful styles. We offer a broad selection of both deck and 3 hole wall-mounted basin mixer taps from luxury brands.

The majority of our three-hole basin mixer taps are manufactured in long-lasting brass material PVD, assuring you of quality and peace of mind. you’ll be able to set a budget, size parameters, finish preferences (gold, chrome, nickel, etc.) all of which will help you to soon discover what the best tap is for you and your bathroom. Whether you’re looking for more of a bold and square tap or an elegant and curved design, you’ll find the perfect design for you here.

What’s great about it?

Gorgeous 3 hole mounted basin mixer tap

PVD GOLD finish

Ceramic disc technology

0.5 bar minimum pressure required

Features:

3 hole deck mounted basin mixer tap

2 separate lever controls for precise temperature and water flow control

PVD GOLD finish

Built from Brass for a robust and reliable construction

Ceramic disc technology for a drip-free tap

Minimum pressure required: 0.5 bar

10-year manufacturer’s guarantee

Dimension:

185*190*100mm

What does PVD stand for?

PVD stands for Physical Vapor Deposition. This state-of-the-art process creates a molecular bond to the faucet resulting in the most durable finish available today. Products with a PVD finish will not corrode, discolor, or tarnish.

How is a PVD finish made?

Chrome-plated parts are meticulously cleaned, then loaded into a vacuum chamber. Once in the chamber, the parts are cleaned on a molecular level using gas ions before an electrical arc is deployed that evaporates metal from a solid target (hence the term “physical vapor deposition”). The vapor molecularly bonds the chrome-plated parts (your future fittings) to form a thin highly adhered metallic layer. During the metal deposition cycle, gases are introduced to react with the metallic layer. This final cycle produces one of our twelve PVD finished colors. The final deposited layer is extremely durable, highly brilliant, and guaranteed for life against tarnishing.

PVD finish care

Wipe dry after each use with a soft dry cloth to prevent water spotting and mineral build-up. We also recommend cleaning regularly with a polish such as Faucet Brite*, which contains both gentle cleansers and a fine wax coating. Alternatively, clean with mild soap and water, then apply a quality car wax or floor paste wax.

Although our PVD finishes are resistant to over 100 cleaning products, we recommend avoiding all products designed to remove tarnish or rust and contain hydrochloric (bleach), hydrofluoric, phosphoric acid, or caustic agents.

Wellness Collection

Wellness Collection

One Piece Suit Closet (WC)

One Piece Suit Closet (WC)

Concealed Cisterns (WC)

Concealed Cisterns (WC)

Faucets Collection

Faucets Collection

Basins

Basins

Mirrors

Mirrors

Whirlpool Jaccuzi

Whirlpool Jaccuzi Wall Hung Closet (WC)

Wall Hung Closet (WC) Intelligent Smart (WC)

Intelligent Smart (WC) Thermostatic Shower Sets

Thermostatic Shower Sets

Art Basins

Art Basins Bathroom Cabinets

Bathroom Cabinets Shower Enclosure

Shower Enclosure

Tankless (WC)

Tankless (WC)

Baby Access Series

Baby Access Series

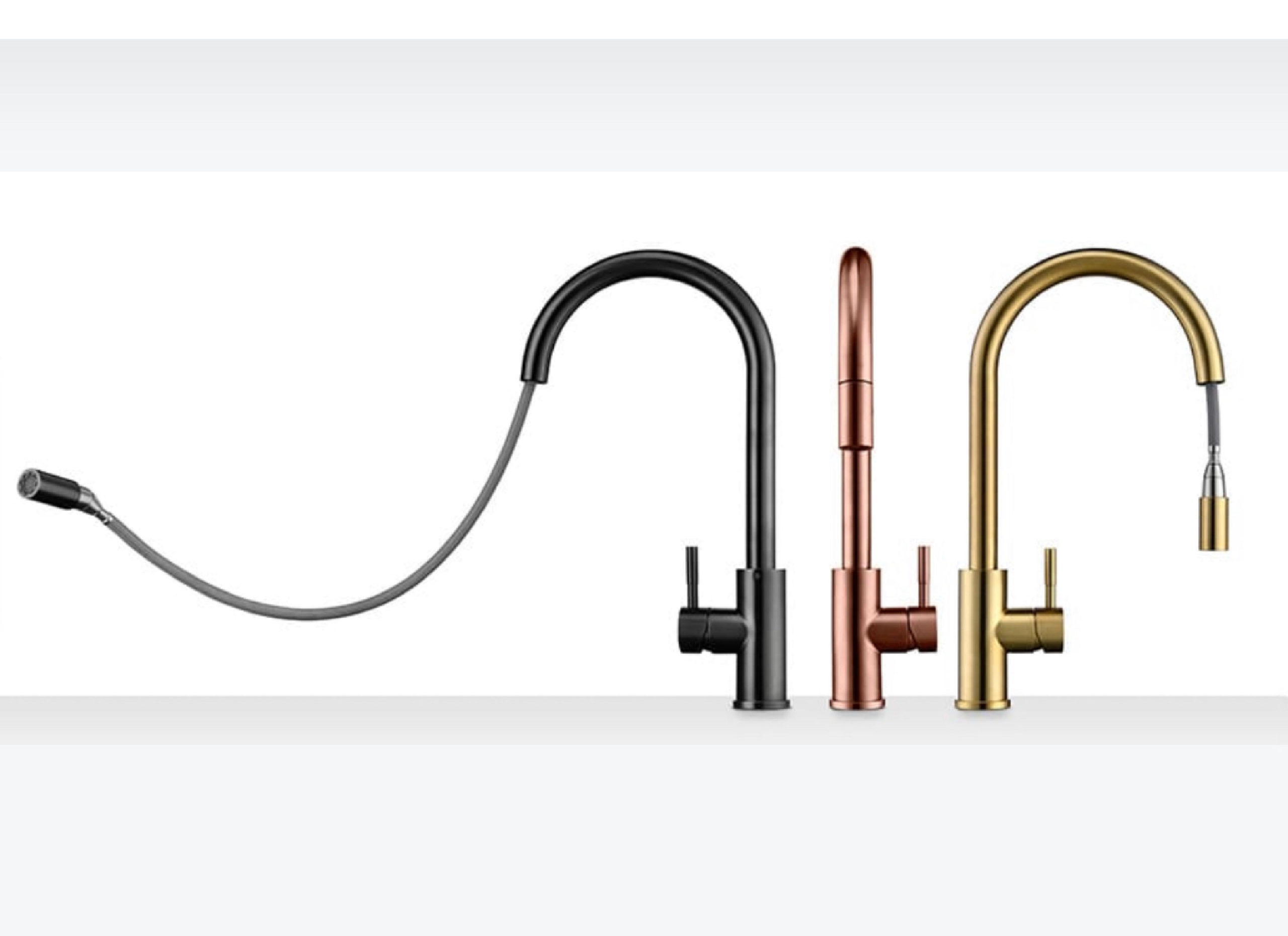

Kitchen Mixer

Kitchen Mixer

Glass Act Basins

Glass Act Basins

Pan & Urinals

Pan & Urinals